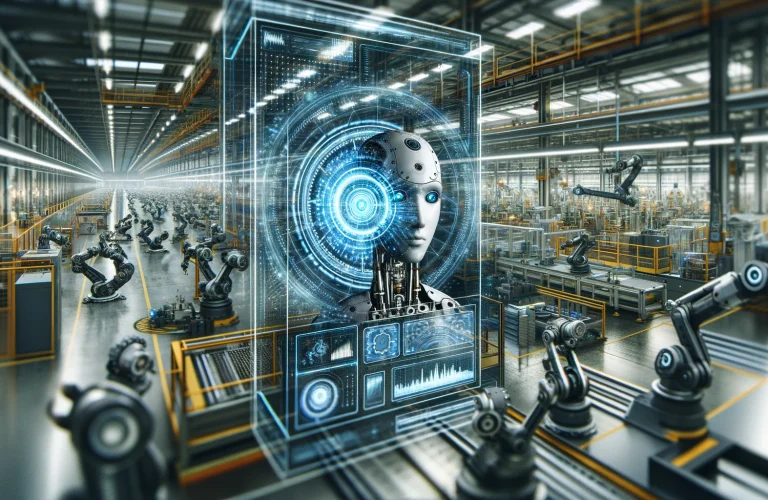

AI and GPT for OEE and Production Efficiency

Exploring the Impact of AI and GPT on Operational Excellence

Operational Efficiency and Effectiveness (OEE) is a standard for measuring manufacturing productivity and a key performance indicator in production management. Integrating Artificial Intelligence (AI) and Generative Pre-trained Transformers (GPT) technologies is revolutionizing this domain by enhancing efficiency and productivity at unprecedented levels.

Harnessing AI for Real-time Data Analysis

AI excels in processing vast amounts of data from production lines to identify patterns and insights that would be unattainable through human analysis alone. This capability is critical in optimizing the three core components of OEE: Availability, Performance, and Quality. By continuously monitoring equipment and production flow, AI helps prevent downtime, maintain consistent operations, and detect quality issues early.

Predictive Maintenance: A Game-Changer

One of the standout applications of AI in production efficiency is predictive maintenance. This technology uses AI to predict equipment failures before they occur, significantly reducing unplanned downtime. By analyzing data from sensors and historical maintenance records, AI algorithms can forecast potential breakdowns and suggest optimal times for maintenance, ensuring machinery is serviced without disrupting production schedules.

GPT: Enhancing Decision-Making and Troubleshooting

Generative Pre-trained Transformers, or GPT, are a type of AI that excels in generating human-like text based on the data it has been trained on. In the context of OEE, GPT can provide substantial support in decision-making processes and troubleshooting.

Real-Time Assistance and Training

GPT applications can assist operators by offering real-time solutions and step-by-step troubleshooting guides directly on the production floor. This immediate assistance helps in swiftly addressing minor issues that could potentially escalate into major problems. Additionally, GPT can be used for training purposes, providing new employees with interactive learning experiences that are informed by real-world scenarios and data.

Combining AI and GPT for Enhanced Operational Insights

When AI’s data analytical power is combined with GPT’s sophisticated language and problem-solving capabilities, the result is a comprehensive tool that enhances every facet of production. This integration not only streamlines operations but also improves decision-making and reduces errors, which are crucial for maintaining high levels of quality and efficiency.

Case Studies: Success Stories in the Industry

Several leading manufacturing companies have significantly improved their OEE scores after integrating AI and GPT technologies. These firms have reported reductions in machine downtime, improved production rates, and better product quality, leading to increased overall profitability.

The Future of Production: AI and GPT at the Forefront

The ongoing development of AI and GPT technologies promises even greater advancements in production efficiency. As these tools become more sophisticated, their ability to learn and adapt to new production challenges will further enhance their effectiveness. This not only supports the goals of operational excellence but also drives innovation in product development and manufacturing processes.

In conclusion, the integration of AI and GPT in production and operational efficiency is transforming the manufacturing industry. These technologies optimize current processes and pave the way for future innovations, ensuring that businesses remain competitive in a rapidly evolving industrial landscape.

Book a demo

Enter your name, company and telephone number below, and we will call and arrange a meeting as soon as possible.

Book a demo

Enter your name and company mail, and we will arrange a demo as soon as possible.